We are targeting 100% circular construction in 2023

We are active on a large number of fronts to achieve circular construction. For years, we have been a frontrunner in the reduction of packaging materials, the use of certified timber and in our material flow analyses. We made another significant effort on all these fronts in 2022. The increasing scarcity of raw materials and the environmental impact of material use are accelerating the need for a system change in material chains. Heijmans is increasingly acting as a director in this chain. As the master of material flows, we feel an enormous responsibility to organise this and bring people together. This requires a different approach to the chain and a thorough methodology.

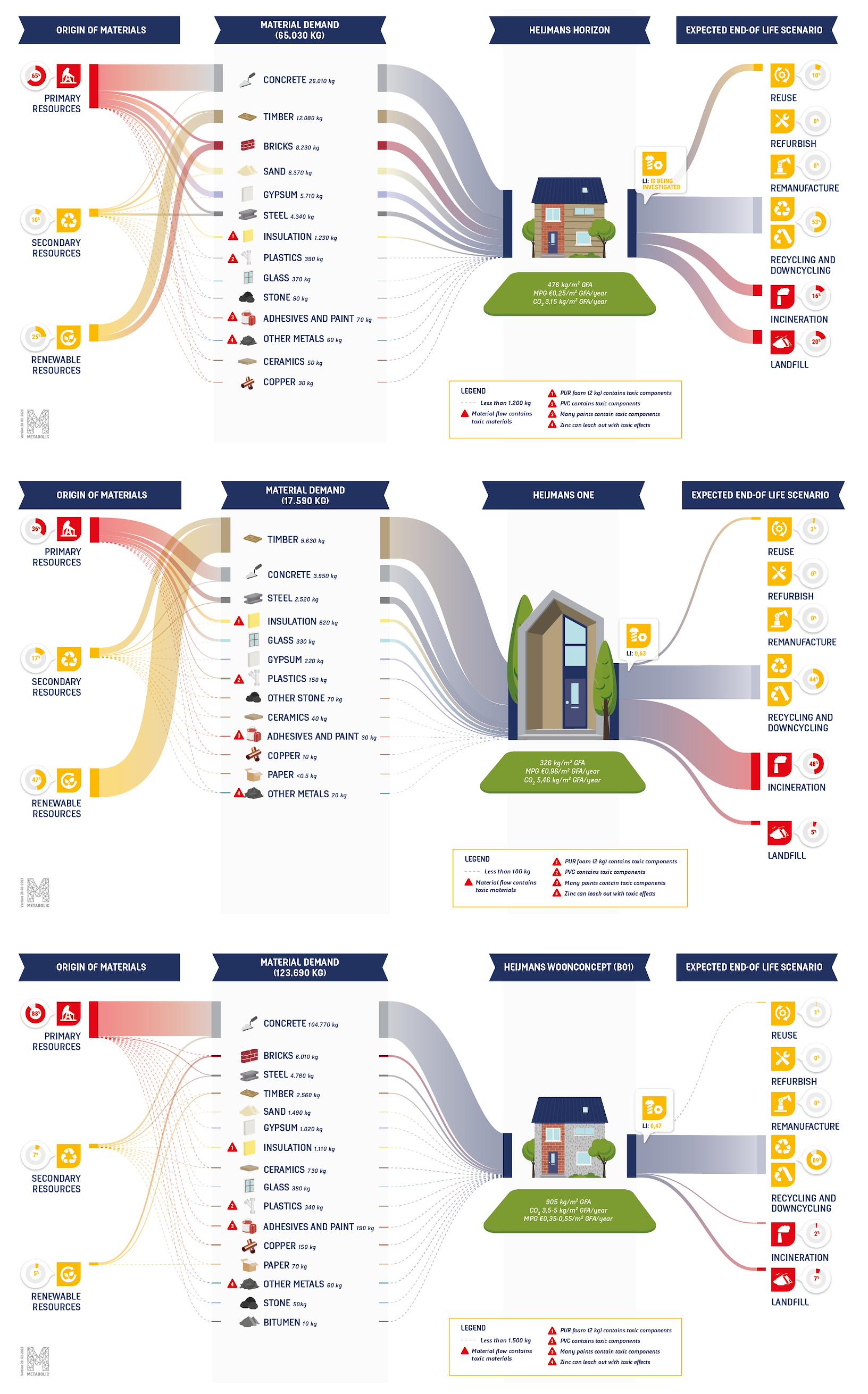

Material flow analysis

Thanks to material flow analyses, Heijmans has more and more insight into the material flows triggered by its projects. This involves both the materials needed in projects and materials released during renovation and demolition. We are using these material flow analyses to take the next step towards circular construction as part of our Sustainable strategic theme. Indeed, in a circular construction sector, a construction company will no longer focus exclusively on the construction phase, but will have an eye for the entire life cycle of materials, and also set requirements for the origin and environmental performance of the materials, plus ensure that the material can be reused easily and healthily in the future. By providing visual insight into the entire material flow with the associated circular performance, Heijmans can accelerate the reduction of the share of primary raw materials, eliminate the concept of waste in phases and reduce the environmental impact of materials. Heijmans introduced material flow analysis in 2021 as a new approach to measuring how circular our structures are. In 2022, the material flow analysis had become the standard approach to making circularity visible within Residential and Non-residential Buildings.

Material flow analysis has also proven valuable in terms of providing insight into the material-related CO2 emissions of material use in our projects. This approach also helps us to measure our scope 3 emissions in accordance with the Greenhouse Gas protocol. Eventually, we want to gain insight into the impact of all our material flows, so we can focus on the most impactful material flows. This is how we are taking our responsibility to make our material flows more sustainable and to focus on circular construction.

Scarcity

Along with the challenges involved in achieving our sustainability ambitions, we are also currently faced with a scarcity of raw materials and other materials and consequently steep price increases. In addition to some minor after-effects of the Covid-19 pandemic, this scarcity is primarily due to the impact of the war in Ukraine and a general shortage of chips. This is having a direct impact on the application of thermal storage systems, boilers, electrical equipment and smart applications. Despite this, we want to stick to our ambitions.

Examples of material flow analyses

Chain approach

At Residential building, we identified the five most harmful materials and discussed alternatives with suppliers. This is how we want to work with our partners to reduce the negative impact of material flows. We see it as our responsibility to take the lead, even if we do not produce our own materials.

Within residential building, concrete is still an important primary raw material and this has a major impact on the environment. This is why we started a monthly consultation with our supplier to jointly explore what we can do to accelerate improvements. On the house construction front, this led to a shift among our co-makers, and we have now reached far-reaching agreements on the use of circular concrete, masonry and plastic products. We now use about 50% concrete granulate in our concrete shells. This results in about 10% lower environmental impact (EQI) and about 10% less use of primary raw materials. In 2023, we plan to increase the percentage of concrete granulate. We have also prepared a pilot project using geopolymer concrete. In 2022, we made preparations for the application of 50% circular PVC window frames as standard in all our concrete concept homes.

Within Non-residential Building, the material flow analysis led to the application of several circular alternatives in the renovation of the Rabobank headquarters in Utrecht. We applied nine circular materials and achieved high-quality reuse of released materials. We achieved this by working with Rabobank to challenge the chain of suppliers, demolition firms and waste processors on this front. For instance, we used high-quality circular concrete, while harmful rock wool was banned from the project. We also reused plasterboard and fitted fully removeable internal walls. Heijmans’ material flow analysis helped Rabobank to define circularity in concrete terms for its organisation and provided insight into which circular criteria the project scored well on.

For the maintenance contract at Hanze University, Heijmans linked the material flow analysis to the BIM models. This made it immediately visible which materials will be released in the short term and which circular opportunities lie ahead for Hanze University.

Infra is also committed to circular construction in a number of ways. From reusing a complete pedestrian bridge, as in Elst, to re-galvanising guide rails along the A79 motorway. More and more projects are working with a Rapid Circular Contract (RCC), aimed at emission-free and circular work. This is resulting in more sustainable choices in both tendering and execution. Where possible, materials are reused immediately, while in other cases reusable project residues are temporarily transferred to a depot, the Circular HUB. This depot has already provided materials for several projects.

In 2020, we started a circularity project at Schiphol Airport related to the concrete transformer pits. Previously, these pits were crushed into concrete granulate by default. The aim was to achieve high-quality reuse, fully in line with the aim of the Concrete Agreement, which states that 94% high-grade reuse of concrete residual flows will be the norm by 2029. After a successful pilot period, the refurbished transformer pit was officially approved by Schiphol in June 2022 for use in (taxiway) runway projects. The number of reused transformers is now approaching 150.

Widening the A1 motorway between Apeldoorn and Twello

To ensure a good flow of (freight) traffic, several sections of the A1 motorway need to be widened, including the section between Twello and Apeldoorn. Heijmans started work on the widening of a 14-kilometre stretch of the road in late 2022. The company will also build two service areas. Our client, the Ministry of Public Works and Waterways (Rijkswaterstaat), wants to be climate neutral and to work in a circular way by 2030 at the latest. Heijmans is keen to put this ambition into action by applying new technologies, reusing materials and using emission-free equipment.

Within the alliance for the Gorinchem-Waardenburg dyke reinforcement project, which includes contractors GMB, de Vries & Van de Wiel and Heijmans plus the Rivierenland Water Board, we are constantly looking, together with our client, for smart ways to use materials as sustainably as possible. Such as a circular approach to earthmoving, with as little soil transport as possible and the maximum reuse of released soil. As a result, of the total two million m³ of soil needed for the new dyke, we managed to reuse some 800,000 m3 of released old dyke material (wet and dry) as core material. On top of this, we managed to process 600,000 m³ of reclaimed material from the floodplain to use directly as new dyke material. This avoided the supply and removal of more than 1.4 million m³ of soil. We also processed the released stone revetment in a variety of circular ways. These include reuse as landfill stone, sweeping material for paving, filter material and mixed granulate.

We were only able to achieve this thanks to good cooperation in the chain. We reached agreements with our subcontractors and landowners in the area for the sale of the land we required, and also for the temporary use of land to process material locally. We also maintained intensive contact with the Rivierenland environmental service, the Zuid-Holland-Zuid (South-Holland-South) environmental service, the Ministry of Public Works and Waterways, the province of Gelderland and the Arnhem region, which gave its approval to carry out the work according to the above working method.

Matching Materials

Heijmans built this digital platform to make material flows visible to the industry, and we have made it available to the construction sector to encourage circularity throughout the chain. We also want to visualise future material flows. If a building is demolished in three years, who can use the material that is released and how should demolition take place? To raise awareness of the possibilities, usefulness and added value of the platform, we organised six speed dates with the market in 2022. These included discussions with architects, waste processors and suppliers to explore how the platform could work best. Meanwhile, the platform has already been successfully deployed within Heijmans and several materials have already been reused in a high-quality manner thanks to Matching Materials.

Week of the Circular Economy

In April 2022, Heijmans once again organised the Circular Economy Week. This was originally an internally focused initiative. At the last edition, the Ministry of Public Works and Water Management and the Government's Central Real Estate Agency, among others, were also actively involved and present. This is in line with our aim to involve external parties even more closely in our ambitions. We are happy to take our responsibility on this front.